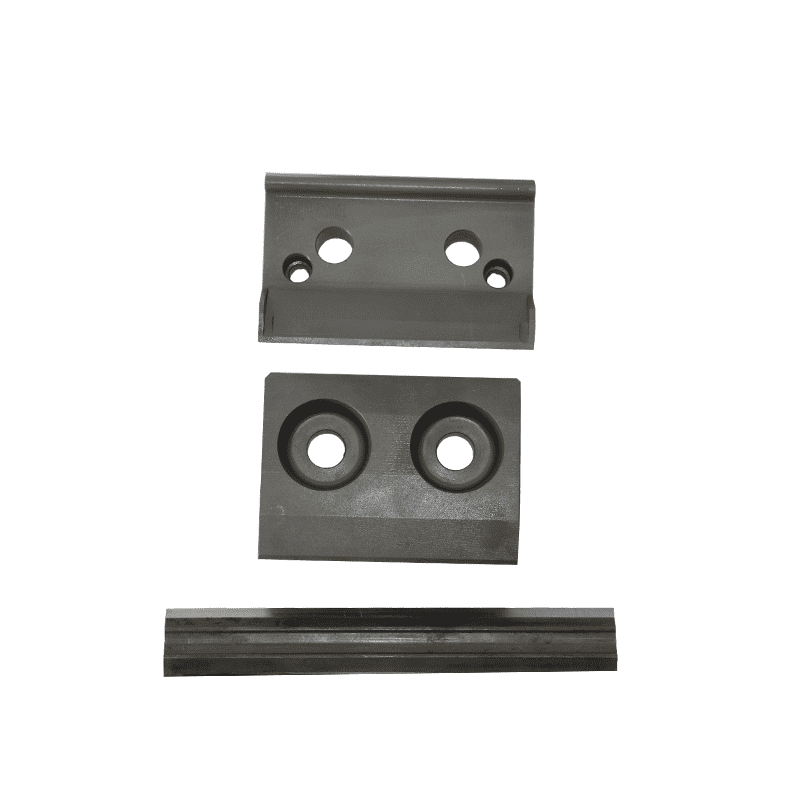

Popular Design for Stainless Steel Auto Body Parts - Custom Machined Parts Used For Wood-Working Machine Parts – Daohong Detail:

Professional Information

|

Inspection Equipment |

CMM, Projector, Calipers, Micro caliper, Thread Micro caliper, Pin gauge, Caliper gauge, Pass meter, Pass meter etc. |

|

Accuracy |

*Accuracy Of Machining:+/-0.005mm *Accuracy Of Grinding:+/-0.005mm *Surface Roughness:Ra0.4 *Parallelism:0.01mm *Verticality:0.01mm *Concentricity:0.01mm |

|

Certificate |

SGS/Material Certificate/Test Report |

|

Drawing Format |

2D Drawings:PDF, DWG/DXF etc. 3D Drawings:IGS,STEP,STP etc. |

|

Diameter |

0.1-25mm |

|

Length |

customization |

|

Roughness |

Ra0.4-Ra0.8 |

| Industry Focus | Appliance/ Automotive/ AgriculturalElectronics/ Industrial/ Marine

Mining/ Hydraulics/ Valves Oil and Gas/ Electrical/ Construction |

| Intended Application | ShaftsValve Components

Automatic Door Components Cable/ Electronic Connector Fire Suppression System Components Fittings/ Fasteners Gears/ Hardware Roller Bearings |

| Lead Times Available | Max: 2 Weeks (On Initial Order)Rush Services Available |

| Industry Standards | ISO 9001:2008PPAP

RoHS Compliant |

| Additional Capabilities | CAD Design ServicesCAM Programming Services

Coordinate Measuring Machines (CMM) Reverse Engineering |

| Equipment List | From simple 2-axis turning to 7-axis, turn-mill-drill CNC Swiss-type machines, we are equipped with a full line of CNC equipment from the following manufactures:molding machines/ stamping machines

automatic lathe machines/ spring machines. |

| Automation Capabilities | Continuous Machining |

| Material(Plastic Polymers) | ABS/ Delrin/ Nylon/ PVC |

| Processes(Special Capabilities) | Broaching/ Hobbing/ Slotting |

Available Materials

| Stainless Steel | SS201,SS301, SS303, SS304, SS316, SS416 etc. |

| Steel | mild steel, Carbon steel,12L14, 12L15,4140, 4340, Q235, Q345B, 20#, 45# etc. |

| Brass | HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. |

| Copper | C11000,C12000,C12000 C36000 etc. |

| Aluminum | AL6061, AL6063, AL6082, AL7075, AL5052, A380 etc. |

Surface Treatment

| Aluminum parts | Stainless Steel parts | Steel parts | Brass parts |

| Clear Anodized | Polishing | Zinc Plating | Nickel Plating |

| Color Anodized | Passivating | Oxide black | chrome plating |

| Sandblast Anodized | Sandblasting | Nickel Plating | Electrophoresis black |

| Chemical Film | Laser engraving | Chrome Plating | Oxide black |

| Brushing | Electrophoresis black | Carburized | Powder coated |

| Polishing | Oxide black | Heat treatment | |

| Chroming | Powder Coated | ||

| Heat Treatment | Tempering | Hardening |

Packing:

| Carton Size | 29*20*13 CM or customer’s request |

| Pallet size | 120*80*80 CM or customer’s request |

| Lead time | 3-7 working days as usual.It will based on the detailed order quantity. |

|

Packing Details |

Method 1: Shrink film, then bulk loading |

| Method 2: Shrink film + box + pallet/ wooden case | |

| Method 3: PP + wooden case | |

| Method 4: As per customers’ requirements or negotiated |

We have 12sets CNC PRECISION AUTOMATIC LATHE to produced machining parts.

The parts have no quantity requirements and our tolerance can control ±0.01MM.

One people can operate 5-6sets machines.

Product detail pictures:

Related Product Guide:

With advanced technologies and facilities, strict quality control, reasonable price, superior service and close co-operation with customers, we are devoted to providing the best value for our customers for Popular Design for Stainless Steel Auto Body Parts - Custom Machined Parts Used For Wood-Working Machine Parts – Daohong, The product will supply to all over the world, such as: Uruguay, Italy, Nigeria, We'll supply much better products with diversified designs and expert services. We sincerely welcome friends from over the world to visit our company and cooperate with us on the basis of long-term and mutual benefits.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly

-

2020 wholesale price Carbon Steel Bicycle Parts...

-

factory customized Stainless Steel Pumps Parts ...

-

Special Design for Cnc Timber Machining Service...

-

Reasonable price for Grass Cutter Spare Parts -...

-

OEM/ODM Manufacturer Wire Extruder Parts - New...

-

High reputation Steel Structure Scaffolding Par...