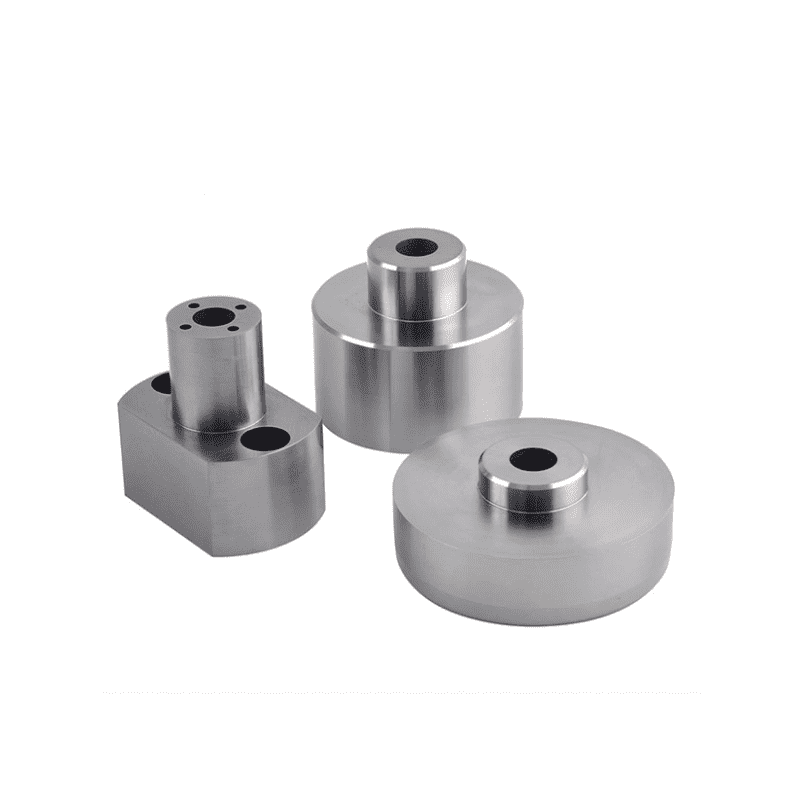

Discount Price Shaft Manufacturing Process - Aluminum Sliding Window Roller Bearing – Daohong Detail:

Professional Information

|

Inspection Equipment |

CMM, Projector, Calipers, Micro caliper, Thread Micro caliper, Pin gauge, Caliper gauge, Pass meter, Pass meter etc. |

|

Accuracy |

*Accuracy Of Machining:+/-0.005mm *Accuracy Of Grinding:+/-0.005mm *Surface Roughness:Ra0.4 *Parallelism:0.01mm *Verticality:0.01mm *Concentricity:0.01mm |

|

Certificate |

SGS/Material Certificate/Test Report |

|

Drawing Format |

2D Drawings:PDF, DWG/DXF etc. 3D Drawings:IGS,STEP,STP etc. |

|

Diameter |

0.1-25mm |

|

Length |

customization |

|

Roughness |

Ra0.4-Ra0.8 |

| Material | CuZn25Al5Mn4Fe3/CuSn8P |

| Typical Application | Machine-tool,Agricultural machinery, Crane electromotor, Spring pin, Steering shaft and transmission, etc. |

| Density g/cm3 | 8.7 |

| Max Dynamic Load N/mm2 | 60 |

| Max Linear Velocity(Grease) m/s | 0.85 |

| Max PV value Grease N/mm2·m/s | 1.65 |

| Pressure strength N/mm2 | >240 |

| Yield Strength N/mm2 | >100 |

| Mating Axis | Hardness ≥40, Roughness 0.4~1.0 |

| Working Temperature ℃ | 40~140 |

| Friction Coefficient | 0.09~0.15 |

| coefficient of heat conduction W/m·K | 52 |

| Linear expansion coefficien | 18.5×10-6/K |

| Product Name | Customized Brass Bushing Metal Bushings For machine car part |

| Material | Stainless steel : 303, 304, 316, 412,201,202 etc Steel: Carbon steel/ die steel, C.R.S etc Aluminum alloy: 6061, 6063, 5052, 2017, 7075,etc Brass alloy:3602, 2604, H59, H62, copper,phosphor bronze,etc Plastic:Nylon,PP,POM,etc Other materials are available |

| SURFACE TREATMENT | Anodizing, Polishing, Powder coating, Passivation, Sandblasting, Nickal plating,Zinc plating, Chrome plating, Heat treatment, Oxidation |

| Produce Progresses | CNCTurning ,CNC Milling ,CNC Lathe etc. |

| EQUIPMETS | CNC punching machines, CNC milling machines, CNC turning machines,CNC machining center, Automatic lathes, Linear cutting, Grinding machine etc. |

| APPLOCATION | Electronic, auto, electric appliance, electrical machine, toy, medical treatment,electronic cigarette spare metal parts,loudspeaker box, furniture and fitness equipment and other industries. |

| MAIN MARKETS | U.S.A, UK, Spain, Germany, Italy, Switzerland, etc |

| FACTORY OR TRADE COMPANY | We are a manufacturing factory. |

Surface Treatment

| Aluminum parts | Stainless Steel parts | Steel parts | Brass parts |

| Clear Anodized | Polishing | Zinc Plating | Nickel Plating |

| Color Anodized | Passivating | Oxide black | chrome plating |

| Sandblast Anodized | Sandblasting | Nickel Plating | Electrophoresis black |

| Chemical Film | Laser engraving | Chrome Plating | Oxide black |

| Brushing | Electrophoresis black | Carburized | Powder coated |

| Polishing | Oxide black | Heat treatment | |

| Chroming | Powder Coated | ||

| Heat Treatment | Tempering | Hardening |

Packing:

| Carton Size | 29*20*13 CM or customer’s request |

| Pallet size | 120*80*80 CM or customer’s request |

| Lead time | 3-7 working days as usual.It will based on the detailed order quantity. |

|

Packing Details |

Method 1: Shrink film, then bulk loading |

| Method 2: Shrink film + box + pallet/ wooden case | |

| Method 3: PP + wooden case | |

| Method 4: As per customers’ requirements or negotiated |

Product detail pictures:

Related Product Guide:

To be able to give you benefit and enlarge our business, we also have inspectors in QC Team and assure you our greatest service and products for Discount Price Shaft Manufacturing Process - Aluminum Sliding Window Roller Bearing – Daohong, The product will supply to all over the world, such as: belarus, Kuwait, Toronto, We follow up the career and aspiration of our elder generation, and we're eager to open up a new prospect in this field, We insist on "Integrity, Profession, Win-win Cooperation", because we have now a strong backup, that are excellent partners with advanced manufacturing lines, abundant technical strength, standard inspection system and good production capacity.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly

-

Rapid Delivery for Phosphor Copper Stamping Par...

-

One of Hottest for Precision Machining Componen...

-

Wholesale Price Steel Rollers Parts - Carbon S...

-

China wholesale Cnc Controlled Machining - Pep...

-

Wholesale Price Cnc Machining Custom - custom ...

-

Factory For Milling And Drilling Machine Parts ...