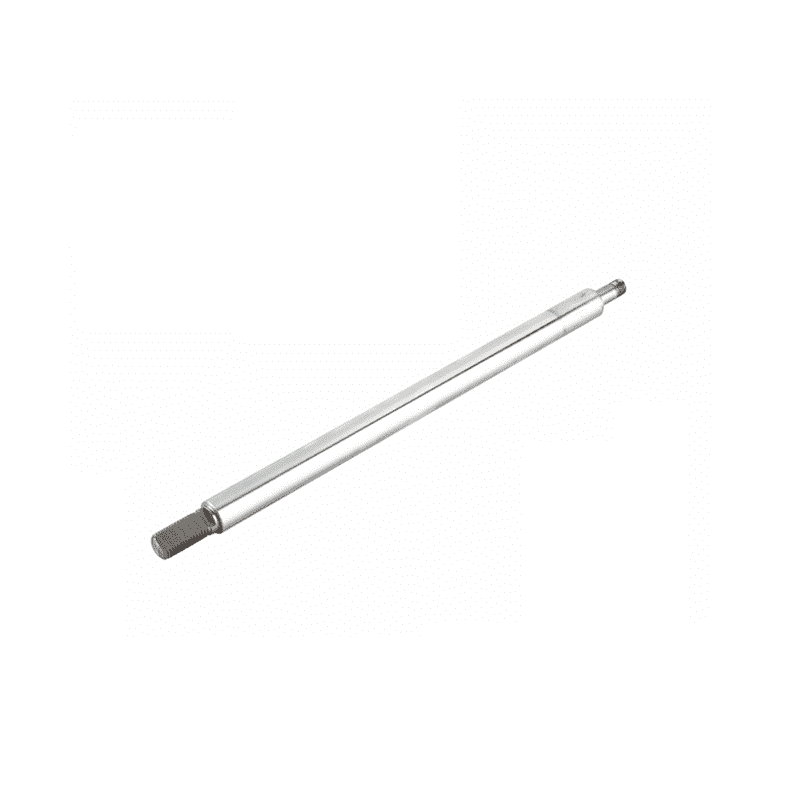

Cheapest Factory Surface Grinding Machine Parts - High Performance Motorcycle Shaft Precision Turning Parts Wear Resistant – Daohong Detail:

Professional Information

|

Inspection Equipment |

CMM, Projector, Calipers, Micro caliper, Thread Micro caliper, Pin gauge, Caliper gauge, Pass meter, Pass meter etc. |

|

Accuracy |

*Accuracy Of Machining:+/-0.005mm |

|

Certificate |

SGS/Material Certificate/Test Report |

|

Drawing Format |

2D Drawings:PDF, DWG/DXF etc. |

|

Diameter |

0.1-25mm |

|

Length |

Customization |

|

Roughness |

Ra0.4-Ra0.8 |

Available materials :

|

Stainless Steel |

SS201,SS301, SS303, SS304, SS316, SS416 etc. |

|

Steel |

mild steel, Carbon steel,12L14, 12L15,4140, 4340, Q235, Q345B, 20#, 45# etc. |

|

Brass |

HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. |

|

Copper |

C11000,C12000,C12000 C36000 etc. |

|

Aluminum |

AL6061, AL6063, AL6082, AL7075, AL5052, A380 etc. |

Surface treatment:

|

Aluminum parts |

Stainless Steel parts |

Steel parts |

Brass parts |

|

Clear Anodized |

Polishing |

Zinc Plating |

Nickel Plating |

|

Color Anodized |

Passivating |

Oxide black |

chrome plating |

|

Sandblast Anodized |

Sandblasting |

Nickel Plating |

Electrophoresis black |

|

Chemical Film |

Laser engraving |

Chrome Plating |

Oxide black |

|

Brushing |

Electrophoresis black |

Carburized |

Powder coated |

|

Polishing |

Oxide black |

Heat treatment |

|

|

Chroming |

Powder Coated |

||

|

Heat Treatment |

Tempering |

Hardening |

Packing:

|

Carton Size |

29*20*13 CM or customer’s request |

|

Pallet size |

120*80*80 CM or customer’s request |

|

Lead time |

3-7 working days as usual.It will based on the detailed order quantity. |

|

Packing Details

|

Method 1: Shrink film, then bulk loading |

|

Method 2: Shrink film + box + pallet/ wooden case |

|

|

Method 3: PP + wooden case |

|

|

Method 4: As per customers’ requirements or negotiated |

Product detail pictures:

Related Product Guide:

owing to excellent assistance, a variety of high quality products and solutions, aggressive costs and efficient delivery, we take pleasure in an excellent popularity amongst our customers. We are an energetic business with wide market for Cheapest Factory Surface Grinding Machine Parts - High Performance Motorcycle Shaft Precision Turning Parts Wear Resistant – Daohong, The product will supply to all over the world, such as: Zambia, Kuala Lumpur, French, All the imported machines effectively control and guarantee the machining precision for the items. Besides, we have a group of high-quality management personnels and professionals, who make the high-quality items and have the ability to develop new merchandise to expand our market home and abroad. We sincerely expect customers come for a blooming business for both of us.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!

-

Hot sale Cnc Subcontract Machining - Child Ant...

-

OEM/ODM Supplier Electric Forge - high demand ...

-

Top Suppliers Aluminium Cnc Machining - Gold D...

-

OEM manufacturer Cnc Router Machining Aluminium...

-

Best-Selling Sheet Metal Duct Parts - Stainles...

-

Hot Selling for Precision Metal Parts - DRIVE ...