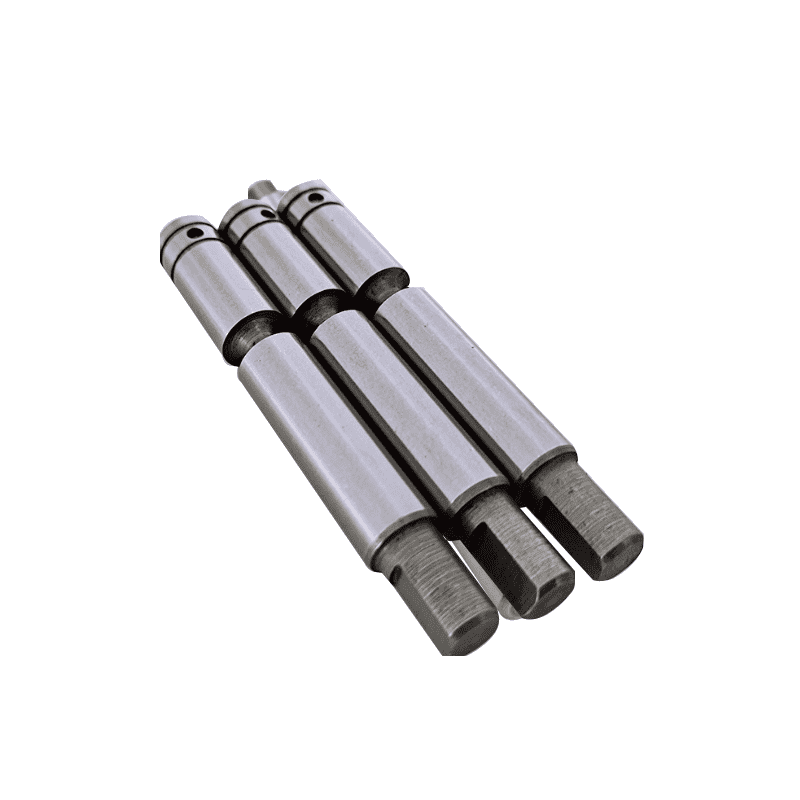

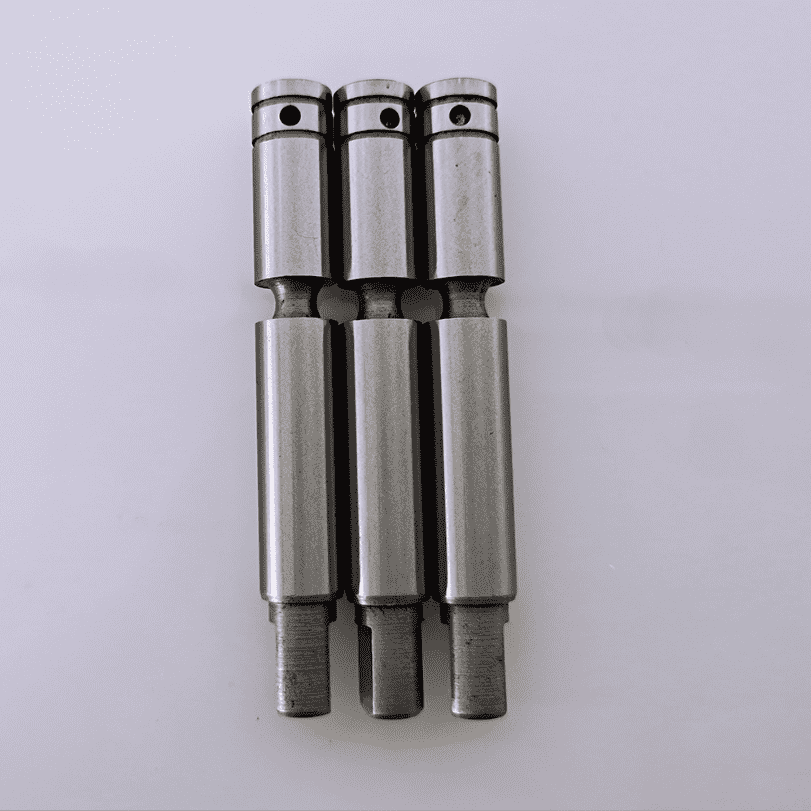

2020 New Style Cnc Large Machining - Automotive Oil Shaft – Daohong Detail:

Professional Information

|

Product name |

Spline gear |

|

Material |

C45,40Cr,20CrMnTi,42CrMo,Copper,Stainless steel and so on as per your requests. |

|

Processing |

Forging,Machining,Hobbing,Milling,Shaving, Grinding,Heat treatment…… |

|

Heat Treatment |

Carburizing,Induction,Flame,Nitriding…… |

|

Main Machines |

Gear Hobbing Machines,Gear Shapers(Gealson,Moude), lathe, gear Shaving machines, gear millling, gear grinding Machines and CNC centers…. |

|

Why choose us |

•100% manufacturer

• Rich production experience •Advanced GEAR Machine •Strict Quality Control System •Flexible MOQ •Punctual delivery •Excellent and Experienced Team |

Regular Materials And Heat Treatment

|

Regular Materials and Heat Treatment |

|||||

|

GB/JB |

DIN |

JIS |

SAE/AISI |

Case Hardening |

Case Hardness |

|

40CrNiMo |

34CrNiMo6 |

SNCM439 |

4340 |

Nitriding |

46-50HRC |

|

20CrMo |

20CrMo44 |

SCT42 |

4119/4118 |

Carburizing |

42-45HRC or 55-60HRC |

|

20CrNiMo |

– |

SNCCM220 |

8620 |

Carburizing |

55-60 HRC or 58-62 HRC |

|

20CrMnTi |

– |

– |

– |

Carburizing |

55-60 HRC |

Heat Treatment Cycle: Carburizing /Nitriding → Normalize → Quench → Clean → Temper → Shot Blast

|

Precision Grade , Process Methods and Application Standard : GB 10095-88,DIN 3961-78;ISO 1328-75/GB 10095-88;JIS 1702-74; AGMA 39003-71

|

|||||

| Precision grade |

Grade 5 |

Grade 6 |

Grade 7 |

Grade 8 |

Grade 9/10 |

| Module range | Gleason M10∼M40 | Spur/helical M3∼M40 |

Spur/helical M3∼M40 |

Spur/helical M3∼M40 |

Spur/helical M3∼M40 |

| Outside Dia(max) |

φ1500mm |

Φ2000mm |

Φ2000mm |

Φ3000mm |

Φ3000mm |

| Final Process |

fine grinding |

fine grinding or shaving |

grinding, shaving , lapping |

shaving |

– |

| Teeth Surface Roughness |

Ra 0.8 μm |

Ra 0.8 μm |

Ra 1.6 μm |

Ra 1.6-3.2 μm |

Ra 3.2-6.3 μm |

| Application |

Measuring gear

|

locomotive

|

craneforging machinetractors,trucksuniversal reducer |

crane farm machinery forging machine tractors,trucks universal reducer |

crane farm machinery forging machine mine machinery tractors |

| Why Choose US | •100% manufacturer |

• Rich production experience

|

•Advanced GEAR Machine

|

•Strict Quality Control System

|

•Flexible MOQ •Fast delivery

|

Packing:

|

Carton Size |

29*20*13 CM or customer’s request |

|

Pallet size |

120*80*80 CM or customer’s request |

|

Lead time |

3-7 working days as usual.It will based on the detailed order quantity. |

|

Packing Details |

Method 1: Shrink film, then bulk loading |

|

Method 2: Shrink film + box + pallet/ wooden case |

|

|

Method 3: PP + wooden case |

|

|

Method 4: As per customers’ requirements or negotiated |

Product detail pictures:

Related Product Guide:

Our business sticks for the basic principle of "Quality could be the life with the firm, and track record will be the soul of it" for 2020 New Style Cnc Large Machining - Automotive Oil Shaft – Daohong, The product will supply to all over the world, such as: Yemen, Victoria, Ethiopia, Facing fierce global market competition, we have launched the brand building strategy and updated the spirit of "human-oriented and faithful service", with an aim to gain global recognition and sustainable development.

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.

-

Lowest Price for Metal Parts - FCS 2 Surfboard...

-

Factory Supply Investment Casting Furnace - ho...

-

High Quality for Cnc Machining Manufacturing Pr...

-

Factory wholesale Anodised Aluminum Cnc Parts -...

-

New Fashion Design for Machined Parts Needed -...

-

Top Quality Stamped Aluminum Parts - Mass prod...